GUEST BLOG: WaterBit Smart Irrigation: Built and Tested for Toughness, Right Here in California

Posted on July 12, 2018 14:06 PM by WGCIT

By Manu Pillai (Co-founder & President) and Leif Chastaine (Co-founder & COO), WaterBit, Inc.

You may have heard about WaterBit through a Western Growers Center for Innovation & Technology event, but there’s something about our products that I bet you don’t know--every WaterBit CarbonTM node and Block Valve ControllerTM is built and tested right here in California.

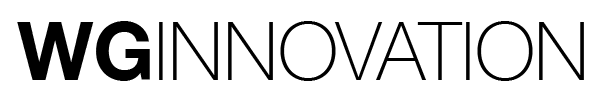

The Carbon node and Block Valve Controller are key parts of our proprietary Automated Irrigation Solution, which enables you to deliver the right amount of water to your crops at the right time. The Carbon node can be paired with a soil moisture sensor to monitor moisture levels in real time, or it can be paired with the Block Valve Controller to turn on and off irrigation valves remotely.

Today, we are going to give you an insider’s look into how we make sure that each Carbon and Block Valve Controller that is installed in the field will stand up to the elements and work maintenance-free.

Quality Control

Quality is in our DNA. Along with experience in the field, many of our team members have roots at Cypress Semiconductor and have spent their careers designing processes to ensure quality at every step of product development. To accomplish our commitment to shipping 100% defect-free products, we’ve kept production in-house, right at our San Jose headquarters. Plus, we rigorously test each unit we build. Below is an overview of our process.

Three Steps to Reliability: Build, Submerge, Bake

Build

In the third photo of the slideshow above, our technicians are assembling Block Valve Controllers. These units, as well as our Carbon nodes, use so little power that their thumb-sized solar panel provide enough energy to run them, even in low light or when tucked under foliage.

Submerge

Although there hasn’t been a whole lot of rain this year, we know our units need to stand up to substantial moisture. Accordingly, each IP67 Carbon is submerged, using a 30-pound barbell to hold it under water for five minutes. This ensures there are no leaks.

Bake

It can get HOT in California, and it’s especially important that irrigation equipment works when temperatures climb. The fourth photo in the slideshow above is of our testing oven, which bakes each unit. By temperature cycling our products, we can assure that each device is mechanically sound and will survive temperatures up to 149°F and down to -40°F.

Innovation and Quality Come Together for California Growers

It’s clear that the members of Western Growers are a forward-thinking group who are constantly innovating in order to survive, and thrive, in California’s competitive economy. We’re proud to have partnered with the Center for Innovation & Technology and to be bringing automated irrigation technology to growers to help them meet labor, water and yield challenges.